This page focuses on core information in the global energy and power industry,covering three key sections:First,Industry Trends,which analyzes policy changes and market demand shifts in energy storage and charging infrastructure across regions like North America,Europe,and Asia-Pacific.Second,Technology Updates,sharing cutting-edge advancements in energy storage battery technology,smart charging pile R&D,and distribution network automation system upgrades.Third,Company News,featuring updates on new product launches,participation in international exhibitions,and global customer collaborations.

The necessity and case analysis of the algorithm for estimating the electrical wear of vacuum circuit breaker contacts in application

The research and development background of the function of estimating electrical wear of vacuum circuit breaker contacts:

With the oil-free process of power system switchgear, vacuum circuit breakers have been rapidly and widely used in power systems due to their many advantages. In China's medium voltage field, vacuum circuit breakers have accounted for over 80%. In 2000, the production of vacuum circuit breakers in China accounted for 87% of the total production of medium voltage circuit breakers 36%, with a market share of 98.85% in 2004.

While the number of vacuum circuit breakers is rapidly increasing, due to their small maintenance requirements and long maintenance cycles, it is easy for users to overlook their electrical life issues. The main factor affecting the electrical life of vacuum circuit breakers is the electrical wear and tear of the contacts. With the passage of time, the first batch of vacuum circuit breakers that have been applied are gradually aging, and the problem is becoming increasingly prominent, which should be given sufficient attention.

Based on the concept of prevention before treatment, prevention is the key. Our company carefully listens to customer feedback (whether the arcing phenomenon can quantify the damage to the circuit breaker contacts when the vacuum circuit breaker is opened with current or fault), and refers to the application of relay protection and related technical literature at home and abroad. Our company has independently developed a contact electrical wear estimation function. In response to the situation where the contacts inside the vacuum tube of the vacuum circuit breaker will be damaged to a certain extent when a fault occurs, we quantify the invisible and untouchable things in a mathematical formula model, issue an alarm, and notify the operation duty personnel to inspect the circuit breaker to eliminate the hidden danger in the bud.

The following is a reference to the fault analysis in Wang Min's article "Synchronous Motor Faults Caused by Poor Contact of Vacuum Circuit Breaker Contacts" to illustrate the necessity of the contact wear estimation algorithm in application.

Fault process:

During equipment inspection, the on duty operator of a certain factory found that the 250KW/6KV synchronous motor equipped with the No. 1 oxygen generator had abnormal operating sound, large motor vibration, and significant up and down oscillation of the stator ammeter pointer in the control cabinet. The machine was immediately shut down. The maintenance electrician found that the secondary output of the C411 current transformer in the 6KV high-voltage cabinet was severely burned out during inspection. They dealt with it and measured the air gap between the synchronous motor stator and rotor. No sweeping phenomenon was found, but the vacuum circuit breaker was not checked. The on duty operator restarted the synchronous motor and within two minutes of operation, the unit experienced the aforementioned fault phenomenon again. At the same time, the fault tripped and shut down. Therefore, engineering and technical personnel were invited to analyze and handle these faults.

Fault handling:

Based on the above-mentioned fault symptoms reported by the operating personnel, the technician conducted a comprehensive inspection of the 6KV high-voltage circuit breaker (ZN9-630A/10KV-20KA vacuum circuit breaker).

1) Measure the insulation condition of synchronous motor and 6KV high-voltage vacuum circuit breaker with a 2500V megohmmeter, and ensure that the phase to phase and ground insulation are within the normal range.

2) Using a three-phase synchronous lamp to check the synchronicity of the vacuum circuit breaker's three-phase contacts during closing, it was found that the three-phase asynchrony exceeded 1mS, with phase C being very poor, and the C synchronous lamp slightly lit up when closed.

3) The contact voltage of the three-phase main contact was measured using a double arm bridge, and the results showed that phase A had 160 micro ohms, phase B had 90 micro ohms, and phase C had 25 ohms, which seriously exceeded the standard (regulations require no more than 50 micro ohms). Adjust and increase the overtravel, but there is no change in the contact resistance of the C-phase. Therefore, it is judged that the contact of the C-phase vacuum arc extinguishing chamber is poor.

4) Replace the C-phase vacuum extinguishing chamber, adjust the three-phase synchronicity to ensure that the three-phase asynchrony is less than 1mS, and test the contact resistance of the three-phase contacts to be less than 50 micro ohms.

After the above processing, the operator restarted the operation, and the motor fault phenomenon was eliminated as in the previous step, and the unit operation returned to normal.

Analysis of the causes and hazards of poor contact of vacuum circuit breaker contacts:

Based on the comprehensive analysis of the above inspection and processing, the direct cause of the large changes in the current of the synchronous motor, abnormal sound of the unit, and large vibration is that the main contact resistance of the C-phase of the 6KV vacuum circuit breaker exceeds the standard, causing poor contact and heating of the contacts, resulting in an imbalance of the three-phase current of the synchronous motor, and thus causing overcurrent tripping fault.

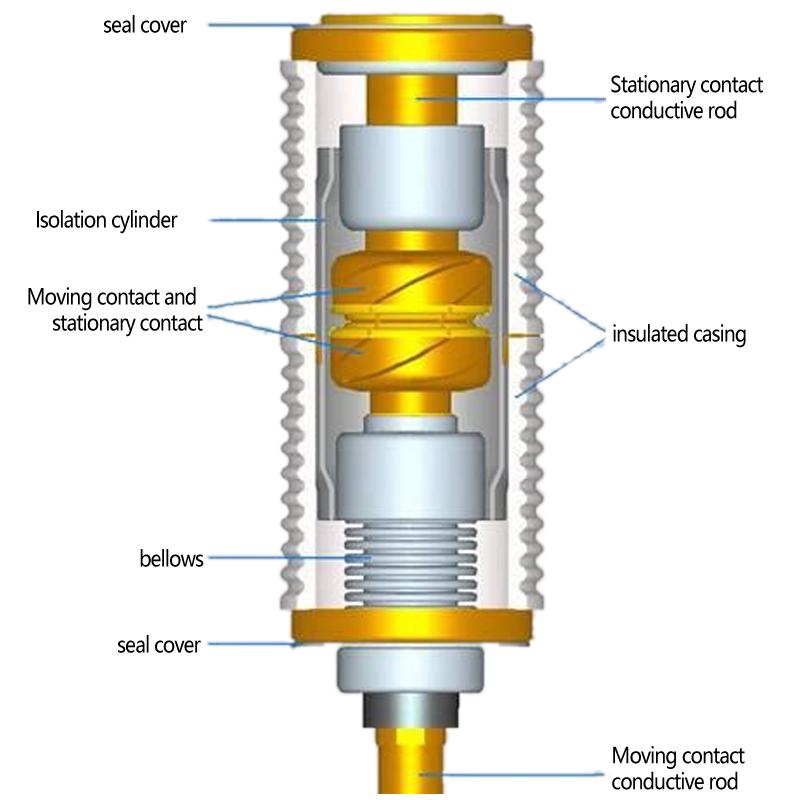

The technicians inspected the replaced vacuum arc extinguishing chamber and found that there was overheating on the moving conductive rod of the vacuum circuit breaker and the outer shell of the vacuum arc extinguishing chamber. Further disassembly of the vacuum arc extinguishing chamber revealed that the active and stationary contact surfaces inside the chamber were severely melted, with uneven surfaces. The three Archimedean spiral grooves on the rotating surfaces of the moving and stationary contacts were melted and blocked, and there were also many contact welding slag falling off the chamber.

Based on the above disassembly inspection results, the technical personnel analyzed that the reason for the severe melting of the dynamic and static contacts of the vacuum circuit breaker is the decrease in contact pressure of the contacts, which leads to a decrease in overtravel caused by contact wear, resulting in an increase in contact resistance and heating during operation. The contacts of a vacuum circuit breaker are made of easily melted multiple materials. When the contacts heat up, they will melt, damaging the surface of the contact's rotating arc and reducing its arc extinguishing ability. The vacuum arc generated during the opening and closing of the circuit breaker accelerates the melting of the contacts, creating a vicious cycle that causes the dynamic and static contacts in the vacuum arc extinguishing chamber to burn out. If the above faults are not dealt with in a timely manner, the vacuum arc extinguishing chamber may explode due to high temperature heating and ineffective arc extinguishing.

Summary:

The arc extinguishing chamber of a vacuum circuit breaker is a non removable sealed whole, and the good contact of the contacts directly affects the electrical quality of the users. Poor contact of the contacts can cause three-phase current imbalance, overcurrent tripping, and high contact resistance, which can lead to high temperature heating and ineffective arc extinguishing, resulting in explosions and other faults.

The electrical wear of vacuum circuit breakers mainly refers to the electrical losses of the arc extinguishing chamber, extinguishing medium, and contacts. It is generally believed that the determining factor is the electrical wear of the contacts. The electrical wear of contacts mainly manifests as net loss of contacts, metal transfer of contact materials, and chemical corrosion. The main factors affecting the electrical wear of contacts include the magnitude of current, the length of arcing time, as well as the contact material, magnetic field structure, and bounce performance.

However, the contact is in the arc extinguishing chamber and cannot be seen or touched. So how do we estimate the wear of the contacts? Grasp the main factors affecting the electrical wear of contacts, such as the magnitude of current and the duration of arcing.

Our company refers to the application of relay protection and research literature on contact wear of vacuum circuit breakers at home and abroad. We have added a contact electrical wear estimation function in the controller, and the algorithm is used for each phase. The wear amount of each time will be added to the previously stored value. When the running count of any phase in the three phases exceeds the set value, the system will issue a warning signal. Notify the operating personnel to conduct a check on the contact resistance, stroke, opening distance, and other parameters of the vacuum circuit breaker contacts, in order to eliminate potential safety hazards in their early stages.

Contact electrical wear estimation algorithm:

As is well known, arc burning loss is closely related to arc energy, and arc energy is closely related to the breaking current and arc ignition time. Our company uses the cumulative amount of electric wear loss (arc energy) per breaking. When the electric wear loss reaches the set value, the controller sends an alarm signal to notify the on duty personnel to inspect the circuit breaker.

The total electric wear loss is equal to the cumulative energy of N arc breaks. The effective value of the breaking current can be easily obtained through high-speed sampling chips, but the arc time is difficult to obtain. In conventional applications, the arc time is generally replaced by the breaking time. However, multiple practices and breaking experiments have shown that using the breaking time instead of the arc time is rela

Recent News